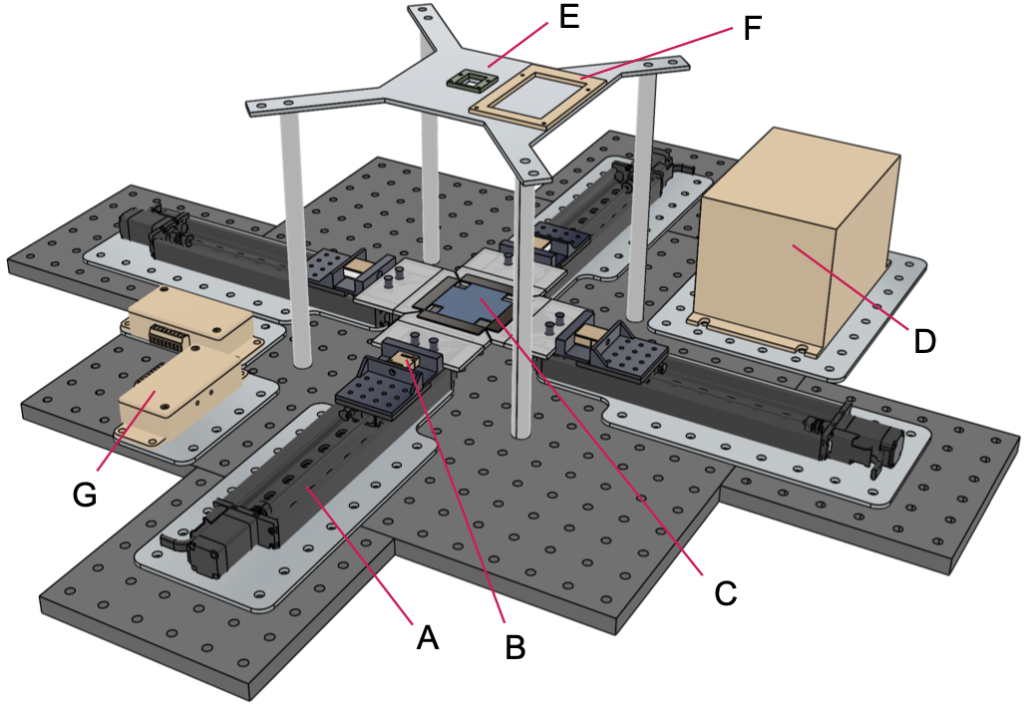

Biaxial testing machine

Biaxial testing is performed to understand the material behavior under multi-directional stresses, which is essential for materials and structures that face complex loading in real-world scenarios. To enable biaxial testing of flexible materials over large strains, we custom built a biaxial stage using commercial load transducers, linear stages and microcontrollers.

| Model | Description | |

| A | Zaber LSM50A | Motorized linear stage |

| B | RES2-5KG | Load transducer |

| C | Cruciform specimens | |

| D | Zaber X-MCC4 | Linear stage controller |

| E | Raspberry Pi 3 | Camera |

| F | Rasyberry Pi 5 | Micro processor |

| G | Loadstar Al-1000 | Amplifier of load transducer |

Four motorized linear stages are positioned orthogonally on a breadboard. Each stage has a maximum displacement of 300mm. Force measurement is facilitated by the load transducers affixed to two orthogonal linear stages. It records data at approximately 5Hz. An overhead Pi Camera 3 is installed above the specimen. All components (4 linear stages, 2 load transducers and the overhead camera) are connected to a Raspberry Pi 5 micro-controller. Through the microcontroller, users can setting of parameters including preload, strain, strain rate, and specimen size.